|

|

|

|

Ron Dickey, Medical Appliance Technician, Prosthetic Orthotic Technician, Walter Reed Army Medical Center, Washington, D.C.

|

1. I chose this career because...

2. My typical workday involves...

3. What I like best/least about my work...

4. My career goals are...

5. When I'm not working, I like to...

|

|

1. I chose this career because...

|

Back to Top

|

|

|

Ron Dickey and his colleagues work in an area of the hospital that has work benches and specialized equipment giving them close proximity to respond to patient needs (top). A high temperature oven is used to melt the plastic (Thermoline) over the form.

|

I chose to become a medical appliance technician because it allows me to be an integral part of helping disabled people regain their mobility and independence.

The Art of Building Boats, Prostheses and Orthoses

After graduating from high school, I worked for a number of years in the repair and manufacture of boats. My grandfather's wide knowledge of tools, and my mother's appreciation of art and design, was influential in my development of hand skills, attention to detail, and creativity.

Eventually, I chose to return to school and continue my education. I wanted a career in a science and health related field that would combine my skills and interests. While researching career possibilities, I found a philosophical similarity between the mechanics of boat building and the making of prostheses and orthoses. They both rely on being structurally strong yet light, comfortable, ultimately safe, and aesthetically handsome. I knew if I could apply my experience with the right education, I might be able to make a difference by helping people who are physically challenged continue with their normal everyday lives. I continued my education at Century College in White Bear Lake, Minnesota. In my opinion, it offers one of the best prosthetic and orthotic technical programs in the country.

College Education

Certification & Professional Membership

- American Board Certified Prosthetic - Orthotic Technician, The American Board for Certification in Orthotics and Prosthetics (http://www.abcop.org/)

|

|

2. My typical workday involves...

|

Back to Top

|

|

|

As shown, there are various phases and materials used when creating a prosthesis, often starting from a foam form (left) and ending with a completed prosthesis (right).

|

My typical workday entails providing technical support to a prosthetist or orthotist by designing and fabricating the best device suited for an individual’s needs. Be it a custom made knee-ankle-foot brace, shoe modification, or an electronic prosthetic leg or arm, the challenge is always unique. In this support role, interaction and communication with the prosthetic or orthotic practitioner is very important. Priorities change as patient needs change. A technician must plan carefully and be prepared for changes in order to deliver the best results. Few things are routine in this field, which makes everyday, a day to learn and experience new tasks.

My Responsibilities

- Reading and interpretation of fabrication forms

- Forming, shaping, laminating, and sewing various plastic braces or prosthetic devices prescribed by the practitioner

- Pouring plaster models

- Keeping updated with the latest technologies and material sciences

Other Duties

- Fine-tuning of a device or on-site repairs

- Keeping inventory and ordering supplies

- Tracking work from start to finish

- Assuring quality and compliance to work orders

- Rendering assistance and sensitivity in prosthetic/orthotic fittings

- Working as a medical team in solving emergency problems

|

|

3. What I like best/least about my work...

|

Back to Top

|

|

|

To make a prosthesis, Ron Dickey first chooses a foam cylinder (top) which fits into a covered hood (center) where it is trimmed to match a patient's stump. Precise measurements of a patient's stump are entered into a software program that dictates the automated sawing of the foam cylinder.

|

What I like best about my work is the need to perceive and visualize a prosthetic or orthotic device as finished to specifications, even before the job starts. To do this, I ask a number of questions. Will the device I make provide the proper range of motion or the support and stability intended? Are there any structural or cosmetic concerns that may need to be identified in the selection of materials? Do I have the correct pigments to mix-and-match a patient’s skin color? Will the location of any suspension aids get in the way of activities, such as riding a bicycle? Does the person plan to go swimming, rock climbing, or play a guitar? Is there a tool that exists to fix an unseen problem, or do I have the time to invent one and prove it will work before four o’clock? Patients are no different than you or I. Outward appearances usually define a job well done, so I always consider the question, “Would I wear it?”

There are many aspects of my work that I find attractive and interesting. Be it bending a metal leg brace for a delicate fit on a child, or laminating a composite socket for an adult amputee to run and finish a race, the results are always encouraging.

What I like least about my work is keeping the lab clean, safe, and productive. Most orthotic/prosthetic labs are equipped with state-of-the-art equipment, such as exhaust hoods for the use of glues and resins, or dust collectors for grinders and routers. Nothing is more reliable than the old-fashioned safety glasses or ear protection for that errant rivet that may come flying off an anvil, or the droning pitch of the many different machines that a technician uses.

Some aspects of my job are routine and time-consuming, but never-the-less important. Whether it’s machine maintenance, keeping the lab free of debris, keeping things in an organized manner, or spending time on the phone ordering supplies and keeping records. It all comes together when a patient returns for his or her new leg, arm, shoe or brace, and leaves with a smile.

|

|

4. My career goals are...

|

Back to Top

|

|

|

Ron Dickey is always conscientious of safety in his work area, and wears safety glasses when using the table saw (top). He uses the fume hood when working with chemicals that can be hazardous if inhaled (botttom).

|

My career goals are to continue to learn from the best and the brightest people that work in the field and to take advantage of the many educational opportunities available through accredited institutions and trade organizations. My plan of attack, for the next two years, is to advance with on-the-job experience and to study the educational requirements for becoming a registered American Board Certified Orthotic Prosthetic Assistant. I may decide to return to school for a bachelors degree, and go on to apply for certification as a prosthetic practitioner.

The field of orthotics and prosthetics has come a long way from the days of birch bark corsets and peg legs. Today’s achievements are nothing short of miraculous. However, the need for more research and development to better understand the psyche and physique of an ever-growing population in need of our service and improved appliances, is wide open.

|

|

5. When I'm not working, I like to...

|

Back to Top

|

|

|

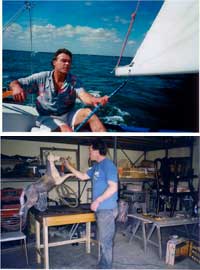

Ron Dickey's favorite pastimes are sailing (top) and restoring antiques (bottom).

|

When I’m not working, I like to stop and appreciate the fine arts and nature. Some of my interests include:

- Listening to classical music and live Blues

- Working with wood and restoring antiques

- Painting

- Reading a good novel

- Being with friends

- Hiking through the woods

My favorite pastime is sailing. Being out on the sea navigating the wind and hearing the slap of the water as it rushes beneath the boat is a real saving grace. One day, I plan to upstart a small fleet of sailboats equipped to handle a day sail for people who are physically challenged, yet capable of leaving the dock and returning on their own.

|

|

|

|

|